وصف المنتج:

النسيج الجيوتيكسيتيل المنسوج هو مادة هندسية متقدمة مصممة لتوفير أداء متفوق في مختلف مشاريع الهندسة المدنية والبناء.المصنوعة باستخدام ألياف البوليستر (PET) والبولي بروبيلين (PP) عالية الجودة، هذا النسيج يقدم متانة استثنائية، وقوة، وموثوقية. مع حجم فتحة تسيطر عليها بعناية تتراوح من 0.05mm إلى 0.2mm، والنسيج يضمن المرشح الأمثل، تصريف،والانفصال، مما يجعلها مثالية لتنفيذ العديد من التطبيقات بما في ذلك تعزيز الهياكل على أرضيات الطرق.

واحدة من الميزات الرئيسية لهذا النسيج الجيوتيكستيل النسيج هو دورها في تعزيز أنظمة سكة الطرق.الطرق والطرق السريعة تتعرض لضغوط مستمرة بسبب عبء المرور والعوامل البيئيةمن خلال دمج هذا النسيج الجيولوجي المعزز والمتثبت في سكة الطريقيمكن للمهندسين تحسين القدرة على تحمل الحمل والمتانة لبنية الرصيف بشكل كبيرالنسيج المنسوج يعمل كطبقة استقرارية تقوم بتوزيع الضغوطات بشكل أكثر تكافؤًا، وتمنع هجرة التربة، وتقلل من التجاعيد والشقوق، وبالتالي تمديد عمر الطريق.

يتم إنتاج النسيج باستخدام مزيج من ألياف البوليستر والبولي بروبيلين ، والتي يشار إليها عادة باسم PET / PP.هذا المزيج يستفيد من أفضل خصائص كل من المواد، في حين أن البولي بروبيلين يوفر مقاومة كيميائية ومرونة. مع معدل إطالة 10٪ ، يمكن أن تستوعب النسيج تشوه معتدل دون فقدان سلامته الهيكلية ،ضمان الأداء على المدى الطويل حتى في ظل ظروف الحمل الديناميكية.

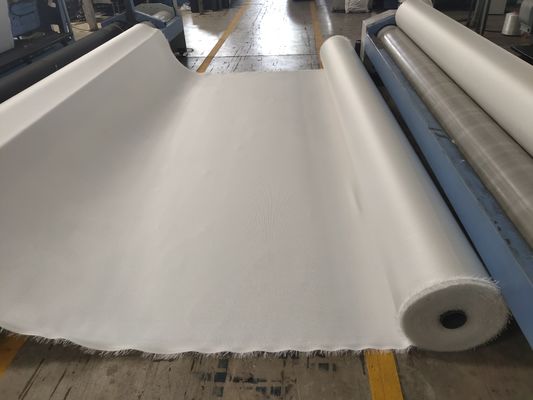

المتوفرة في أطوال تتراوح من 50 متر إلى 100 متر ، والنسيج الجيوتيكسيتيل المنسوج هو متعدد الاستخدامات ومريحة لمختلف أحجام المشاريع.سواء كان عملاً على نطاق صغير في مجال المناظر الطبيعية أو مشروع بنية تحتية كبيريسمح خيارات الطول القابل للتخصيص للنسيج بتغطية فعالة والحد الأدنى من النفايات. بالإضافة إلى ذلك ، تتوفر الخيارات في لونين: الأبيض والأسود.غالبًا ما يفضل النسخة البيضاء للتطبيقات التي تكون فيها الرؤية وانعكاس الحرارة مهمة، في حين أن النسيج الأسود يقدم مقاومة فائقة للأشعة فوق البنفسجية ويستخدم عادة في البيئات الخارجية المعرضة لأشعة الشمس.

حجم الفتحة من 0.05-0.2 ملم هو معيار حاسم يحدد أداء تصفية النسيج وتصريفه.هذا النطاق الدقيق يضمن أن النسيج يمكن أن يفصل بشكل فعال جزيئات التربة مع السماح للمياه أن تمر بحريةهذه الوظيفة ضرورية لمنع تآكل التربة والحفاظ على استقرار التربة، وخاصة في تعزيز أرضيات الطرق حيث تدخل المياه وإدارة الصرف الحاسم.يساعد الصرف الصحيح الذي يسهله نسيج النسيج الجوي على تقليل الضغط الهيدروستاتيكي ويمنع تراكم المياه التي يمكن أن تضعف أسس الطريق.

بالإضافة إلى تعزيز أرضيات الطرق، يستخدم هذا النسيج الجيوتيكسيتيل المنسوج على نطاق واسع لتثبيت التربة، ومكافحة التآكل، وحماية المنحدرات، ودعم الجدران.وقدراتها العالية على تعزيزها وتثبيتها تجعلها خيارًا موثوقًا لتحسين الخصائص الميكانيكية للتربة وتعزيز الأداء الهيكلي العام لمشاريع البناءيضمن مزيج من مواد PET / PP مقاومة ممتازة للتحلل البيولوجي والكيميائي ، فضلا عن قوة سحب عالية ،وهو أمر حيوي للحفاظ على الاستقرار في ظل ظروف بيئية قاسية.

عملية تصنيع هذا النسيج الجيوتيكسيتيل النسيج تنطوي على ترابط الألياف من PET و PP بشكل وثيق في نمط التشابك والترابط ، مما يؤدي إلى هيكل قوي ومستقر.هذا التصميم المنسوج يوفر قوة سحب أكبر مقارنة بالبدائل غير المنسوجة، مما يجعلها مناسبة بشكل خاص للتطبيقات الثقيلة مثل بناء الطرق والأعمال الأرضية.القدرة على مقاومة الإجهاد الميكانيكي مع الحفاظ على المرونة تسمح لها بالتكيف مع الأسطح غير المتكافئة، وتوفير تعزيز التربة والاستقرار الشامل.

بشكل عام، النسيج الجيوتيكسيتيل المنسوج هو مادة لا غنى عنها لمشاريع الهندسة المدنية الحديثة التي تتطلب تعزيز فعال لأنظمة أسطح الطرق وتثبيت التربة.مزيجها من مواد PET/PP، حجم الفتحة الدقيق، القدرة على التمدد، وخيارات الألوان المتاحة تجعله حلًا جيوسنتيسيًا متعدد الأداء عالي الأداء.يمكنك الحصول على متانة متزايدة، تحسين توزيع الحمل، والاستقرار الهيكلي على المدى الطويل، وضمان نجاح واستدامة استثمارات البنية التحتية الخاصة بك.

الخصائص:

- اسم المنتج: نسيج من النسيج الجيولوجي

- المواد: البوليستر/البولي بروبيلين من أجل المتانة والقوة

- الطول: 10 ٪ لاستيعاب حركة الأرض

- قوة الشد: تتراوح من 50KN / m إلى 1200KN / m تضمن مقاومة عالية للتوتر

- العرض: 5.2 متر مناسبة لتغطية مساحة كبيرة

- قوة ثقب CBR: ≥12KN توفر مقاومة ممتازة للثقوب

- يحتوي على بنية مركبة فريدة من نوعها للقاعدة الشبكة لتعزيز

- مصممة مع هيكل مركب للشبكة لتحسين المتانة والاستقرار

- يقدم خسائر إنشاء وتثبيت منخفضة، مما يجعلها فعالة من حيث التكلفة وكفؤة في الاستخدام

المعلمات التقنية:

| حجم الفتحة |

0.05-0.2ملم |

| قوة الشد |

50KN/m - 1200KN/m |

| العرض |

5.2م |

| المواد |

البوليستر/البولي بروبيلين (PET/PP) |

| الطول |

10% |

| اللون |

أبيض، أسود |

| قوة ثقب CBR |

≥12KN |

| الطول |

50م - 100م |

| الوصف |

النسيج الجيوتيكسيتيل المنسوج المعزز للغاية والمستقر مع مادة PET / PP مع بنية مركبة من شبكة القمامة. |

التطبيقات:

نسيج الجيوتيكسيتيل المنسوج من HAISAN ، من CN ، هو منتج استثنائي مصمم لتلبية المتطلبات الصارمة لمختلف مشاريع الهندسة المدنية والبناء.مع قوة ثقب CBR ≥ 12KN ومعدل إطالة 10%يقدم هذا النسيج الجيوتيكسيتيل متانة مرنة متميزة، مما يجعله مثاليا لتعزيز الأرض الرخوة في البيئات الصعبة.2 متر وطول قابل للتخصيص يتراوح من 50m إلى 100m يوفر تنوع وسهولة التثبيت، تلبية متطلبات المشروع المتنوعة.

واحدة من المناسبات الأساسية للتطبيق للنسيج الجيوتيكسيتيل المنسوج HAISAN هي في تعزيز الأرض حيث تسود ظروف التربة الناعمة وغير المستقرة.من خلال دمج هذا النسيج في عملية البناء، يمكن للمهندسين تحسين استقرار التربة وتوزيع الحمل بشكل كبير، ومنع تآكل التربة والانحلال بفعالية.قدرة النسيج على تحمل قوى ثقبية عالية يضمن أداء طويل الأمد حتى في ظل الإجهاد الميكانيكي الشديد، وهو أمر بالغ الأهمية في بناء الطرق والسدود وتثبيت الأساس.

سيناريو تطبيق آخر حيوي هو تنفيذ الهيكل المركب للشبكة.هذه التقنية الهندسية المتقدمة تجمع بين الركائز مع شبكة من النسيج الجيوتيكستيل لتعزيز القدرة على تحمل الأرض وتقليل التسويةنسيج هايسان، متوفر في اللونين الأبيض والأسود، مناسب تماما لمثل هذه الهياكل المركبة بسبب قوته المتفوقة وخصائص التمدد.من خلال دمج الهيكل المركب للشبكة، وتحقيق مشاريع البناء تحسين نقل الحمل وتحسين الاستقرار العام، وخاصة في ظروف التربة الضعيفة.

وعلاوة على ذلك، يستخدم نسيج الجيوتيكستيل المنسوج من HAISAN على نطاق واسع في مجال المناظر الطبيعية وأنظمة الصرف الصحي ومشاريع مكافحة التآكل.تمكن من دخول المياه من خلالها مع احتجاز جزيئات التربة، وهو أمر ضروري للحفاظ على سلامة التربة في المنحدرات والسدود. خصائص النسيج المادية القوية تجعله خيارًا موثوقًا لمختلف مشاريع البنية التحتية،بما في ذلك الطرق السريعة، السكك الحديدية، ومدارات المطارات، حيث الأداء المتسق والمتانة هي أهمية قصوى.

باختصار، النسيج الجيوتيكستيل المنسوج من HAISAN هو مادة لا غنى عنها لتعزيز الأرض الرخوة وبناء الهياكل المركبة الشبكة.إطالة مسيطرة، والعرض الواسع، والأطوال المتاحة تجعلها قابلة للتكيف مع العديد من سيناريوهات الهندسة، وضمان تحسين استقرار التربة، وطول العمر، والسلامة في مشاريع البناء في قطاعات متعددة.

التخصيص:

تقدم HAISAN نسيج جيوتيكستيل مخصص مخصص لاحتياجات مشروعك المحددةضمان المتانة والأداء الممتازمع عرض 5.2m وأطوال تتراوح من 50m إلى 100m، ونحن نقدم خيارات الحجم مرنة لتناسب تطبيقات مختلفة.

يحتوي نسيجنا على امتداد بنسبة 10٪ وقوة سحب تتراوح بين 50KN / m و 1200KN / m ، مما يجعله مثاليًا لتعزيز الأرض الرخوة ومشاريع معالجة الأرض الرخوة.فهي فعالة بشكل خاص في تعزيز الهياكل الطرق، وتعزيز الاستقرار وطول العمر.

ثق بـ (هايسان) للحصول على نسيج جيوتيكستيل نسيج عالي الأداء وموثوق به مخصص لدعم متطلبات البناء والهندسة الخاصة بك

الدعم والخدمات:

نسيجنا المنسوج من النسيج الجيولوجي تم تصميمه لتوفير قوة متفوقة ومتانة لمجموعة متنوعة من التطبيقات الهندسية المدنية والمنظر الطبيعيفريقنا من الخبراء متاح للمساعدة في اختيار المنتج، إرشادات التثبيت، وتحسين الأداء لضمان نجاح مشروعك.

نحن نقدم خدمات شاملة بما في ذلك تقييم الموقع، التصنيع حسب الطلب، والحلول المخصصة لتلبية متطلبات المشروع المحددة.نحن نقدم كتيبات تثبيت مفصلة والمساعدة التقنية في الموقع لضمان التنفيذ السليم والكفاءة القصوى للنسيج الجيوتيكستيل.

بالنسبة للصيانة وإصلاح الأخطاء، تشمل خدمات الدعم لدينا بروتوكولات التفتيش والتوصيات لتمديد عمر النسيج في مختلف الظروف البيئية.نحن ملتزمون بتقديم منتجات عالية الجودة مدعومة بدعم فني موثوق به وخدمة العملاء.

سواء كنت بحاجة إلى مساعدة مع مواصفات تحمل الحمل، حلول الصرف الصحي، أو مكافحة التآكل، فريقنا على استعداد لتوفير التوجيه والدعم الخبراء طوال دورة حياة مشروعك.

التعبئة والشحن:

ويتم لف النسيج الجيوتيكسيتيل المنسوج بعناية ويتم تغليفه ببلاستيك وقائي لمنع التلف أثناء التعامل والنقل.ثم يتم وضع كل لفة بشكل آمن على منصات صلبة لضمان الاستقرار وسهولة التحميل.

للشحن، يتم تغليف الحافلات وتقييدها لتجنب الحركة والتلوث.نحن نقدم خيارات شحن متعددة بما في ذلك شحن الحاويات للطلبات الكبيرة وخدمات الشحن على لوحات للكميات الصغيرة.

يتم اختيار جميع مواد التعبئة والتغليف لتحمل ظروف الطقس المختلفة، مما يضمن وصول المنتج في حالة مثالية.تتوفر حلول التعبئة والتغليف المخصصة عند الطلب لتلبية متطلبات المشروع الخاصة.

الأسئلة الشائعة:

س1: ما هو اسم العلامة التجارية للنسيج الجيوتيكسيتيل المنسوج؟

ج1: اسم العلامة التجارية للنسيج الجيوتيكسيتيل المنسوج هو HAISAN.

س2: أين يتم تصنيع نسيج الجيوتيكستيل المنسوج من HAISAN؟

ج2: نسيج HAISAN النسيج الجيوتيكسيتيل المصنوع في الصين (CN).

السؤال 3: ما هي التطبيقات الشائعة للنسيج الجيوتيكستيل المنسوج من HAISAN؟

A3: يتم استخدام HAISAN النسيج الجيوتيكستيل النسيج بشكل شائع لتحقيق الاستقرار في التربة ومكافحة التآكل والصرف وتعزيز في مشاريع البناء والبناء.

السؤال 4: ما هي المواد المستخدمة لصنع نسيج الجيوتيكستيل المنسوج من HAISAN؟

ج4: عادة ما تكون نسيج HAISAN Woven Geotextile مصنوع من ألياف البولي بروبيلين أو البوليستر عالية القوة المنسوجة معًا لتوفير المتانة والاستقرار.

السؤال 5: كيف تفيد نسيج HAISAN للنسيج الجيوتيكستيل بمشاريع البناء؟

ج5: يزيد النسيج من قوة التربة، ويمنع تآكل التربة، ويسهل تصريف المياه، ويمدد عمر الهياكل البناءية من خلال توفير التعزيز.

يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!  يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!